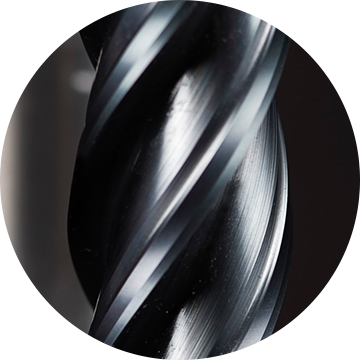

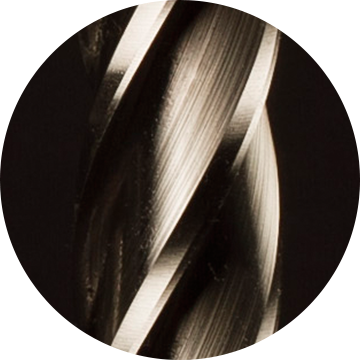

Brazed Carbide

Brazed Carbide works using a solid steel body and carbide tip; the steel drives, while the carbide tip slices with ultimate precision. For high accuracy jobs, the carbide brazed tool remains the ultimate solution. Aside from its strength, brazed carbide provides a cheaper alternative to solid carbide which is more durable, and less prone to snapping.

The benefits of working with brazed carbide tipped tools are many. For example; with carbide tipped drills, higher feeds and speeds are achievable. Also, tools will maintain size and are more durable to wear and tear. Moreover, cutting edges are more resistant to high-temperature machining.