Reduced Downtime

Need something fast that you can’t buy off the shelf? Give us a call. We can repair or replace your tooling in order to minimise your downtime and keep your production lines running.

Need something fast that you can’t buy off the shelf? Give us a call. We can repair or replace your tooling in order to minimise your downtime and keep your production lines running.

Operating within your stipulated parameters, we'll design your specific tooling package. We'll complete the job with precision, and rapid turnaround time; optimising your productivity and profitability.

Return on investment and profitability are of course key drivers and we know that. By retipping, regrinding or coating your tooling you will extend their life and maximise cost effectiveness.

Need something fast that you can’t buy off the shelf? Give us a call. We can repair or replace your tooling in order to minimise your downtime and keep your production lines running.

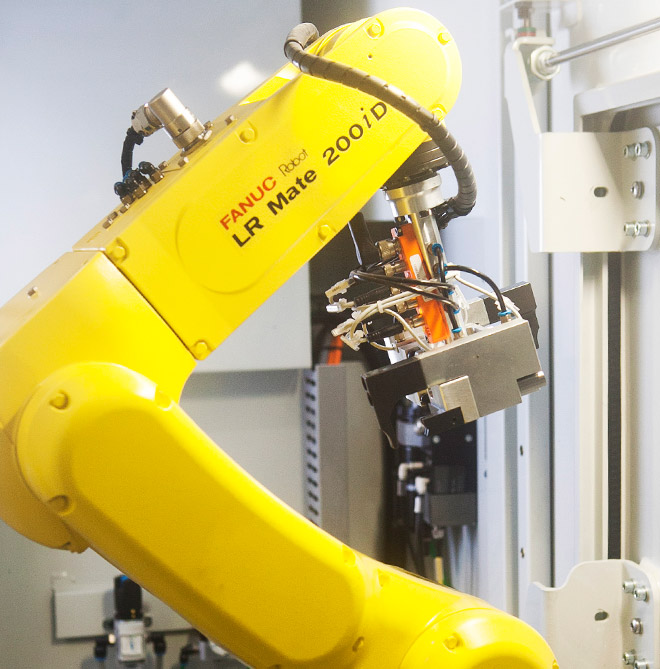

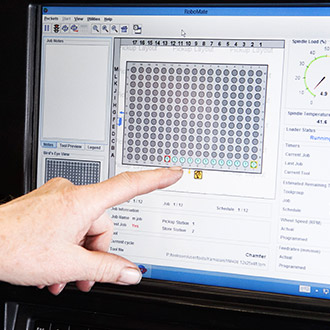

Thanks to increasingly intelligent CNC tool and cutter grinders and software systems that streamline cutting tool manufacture, custom cutting tools arrive to your agreed lead times and budget.

Return on investment and profitability are of course key drivers and we know that. By retipping, regrinding or coating your tooling you will extend their life and maximise cost effectiveness.

Need something fast that you can’t buy off the shelf? Give us a call. We can repair or replace your tooling in order to minimise your downtime and keep your production lines running.

Our investment in the latest in-house inspection technology, with equipment calibrated to an exacting standard, means tolerances are microscopic and flawless.

Return on investment and profitability are of course key drivers and we know that. By retipping, regrinding or coating your tooling you will extend their life and maximise cost effectiveness.

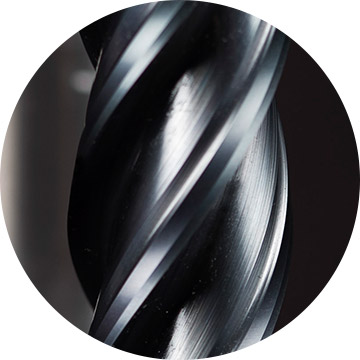

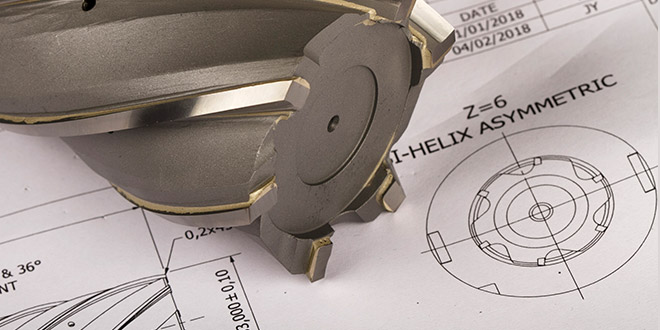

Brazed Carbide works using a solid steel body and carbide tip; the steel drives, while the carbide tip slices with ultimate precision.

Solid Carbide is an excellent option for process security, manufacturing cost-effectiveness and high-grade hole quality.

High-speed steel (HSS or HS) - a class of high alloy steels - are capable of withstanding higher temperatures without losing temper.

Operating within your stipulated parameters, we'll design your specific tooling package. We'll complete the job with precision, and rapid turnaround time; optimising your productivity and profitability.

Whatever you need, ask us. We are a solutions based company, there is every chance we can help. Specials are our lifeblood. We’re good friends to have.

Our investment in the latest in-house inspection technology, with equipment calibrated to an exacting standard, means tolerances are microscopic and flawless.

Operating within your stipulated parameters, we'll design your specific tooling package. We'll complete the job with precision, and rapid turnaround time; optimising your productivity and profitability.

Whatever you need, ask us. We are a solutions based company, there is every chance we can help. Specials are our lifeblood. We’re good partners to have.

Our investment in the latest in-house inspection technology, with equipment calibrated to an exacting standard, means tolerances are microscopic and flawless.

Need something fast that you can’t buy off the shelf? Give us a call. We can repair or replace your tooling in order to minimise your downtime and keep your production lines running.

Thanks to increasingly intelligent CNC tool and cutter grinders and software systems that streamline cutting tool manufacture, custom cutting tools arrive to your agreed lead times and budget.

Return on investment and profitability are of course key drivers and we know that. By re-tipping, re-grinding or coating your tooling you will extend their life and maximise cost effectiveness.

By reducing friction, oxidation risks and general wear, we enable your tools to perform to the absolute best of their abilities. Tool coating also aids in lowering metal fatigue and increases thermal resistance as well.

Furthermore, the various coatings utilised in our recoating service successfully enhance tool performance, providing a new lease of life when combined with our refurbishing services.

Coated tools speed up production and diminish overall costs. Reducing machining times coated cutting tools can be worked with considerably higher cutting parameters than uncoated ones; this cuts expenses significantly. Extended tool life means fewer tool replacements; therefore reducing manufacturing costs.

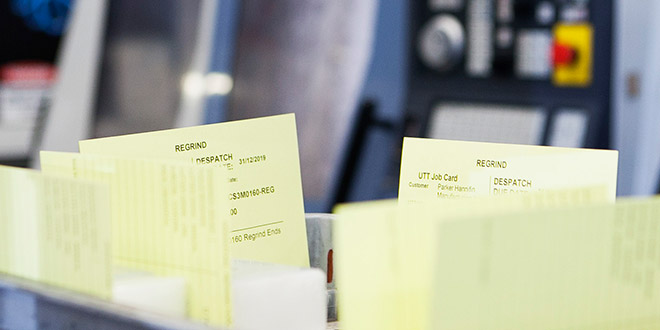

This cost-effective method regrinds your tooling, enhancing performance and saving thousands of pounds in new equipment. Regrinding will offer you the equivalent level of productivity you'd achieve with brand new tools.

UTT's regrinding service renders tools like-new; original performances at a fraction of the cost of replacement. Correct tool management means higher production efficiencies. The moment a tool is worn, you are already paying the price.

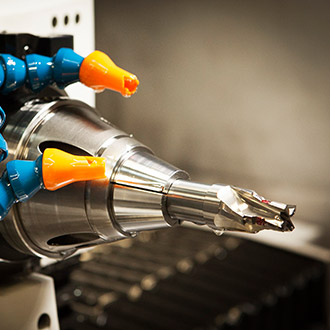

Employing our five-axis CNC grinding machines allows us to reach new heights in regrinding quality and consistency, and forms inspected using 100x cameras. With UTT, you know your tooling will arrive on time within budget and to the highest standards and tolerances.

Replacement carbide tips provide ultimate strength and durability while utilising the existing steel body maintains cost-effectiveness. Resharpening the tips then brings the tooling back to its original specs. Simply put, this service renders old tooling as good as brand-new!

The moment a tool is worn, you are already losing. Retipping means efficient tool management, cost-reduction and improved profit. By reconditioning tools to their primary dimensions via replacing the carbide blades, including helical tips and regrinding to the tool’s original dimensions; UTT's retipping service restores original performances by 100%.

At UTT, we harness the power of CNC technologies, CAD, and 3D simulation software. Committed to providing you with the highest quality precision manufactured cutting tools; from concept to build, UTT delivers excellence, every time.

At UTT, we utilise CAD (computer-aided design). Our experienced engineers work combine their craftsmanship with the latest technology, offering design insight to improve finish quality or process speed further.

This system, thanks to its data-sharing abilities, has facilitated superior quality and precision. Moreover, it has increased designer productivity and capability.

At UTT, we believe in keeping a finger on the pulse of the ever-evolving world of tech. Our investment in the most advanced, state-of-the-art CNC machinery means we can deliver outstanding accuracy at rapid delivery times, regardless of job size.

CAD design, combined with cutting edge CNC machinery and an old school eye for detail – UTT strive for tooling perfection

Whatever industry you may be in, if you want to work with a tooling company you can trust, then look no further. We are skilled, experienced and knowledgeable; so please give us a call on 0116 2347 840 or drop us an enquiry: